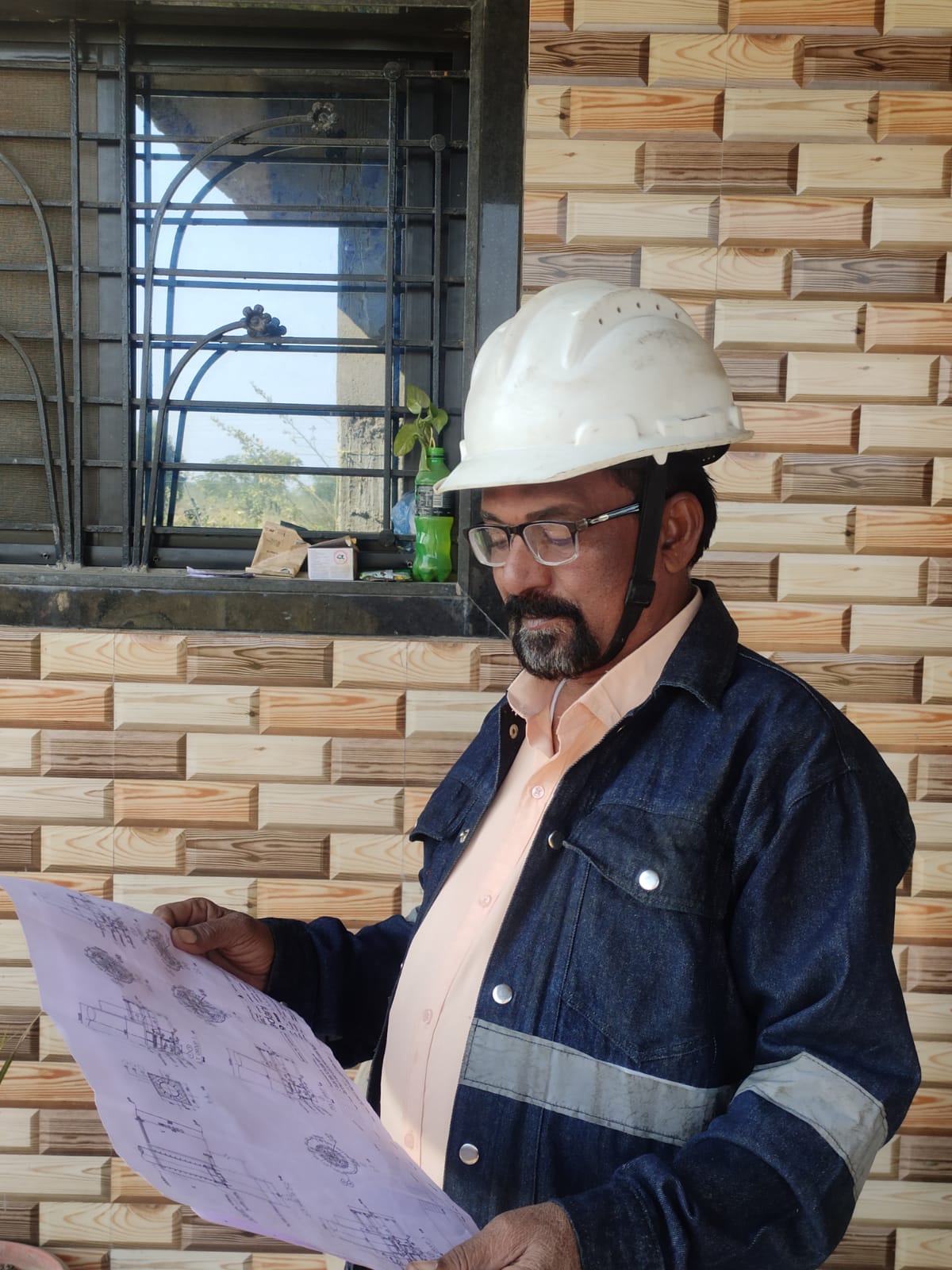

Excellence in Engineering

Project & Maintenance Management

Providing world-class technical solutions for cement plants worldwide with 40+ years of industry expertise.